Our epoxy resins

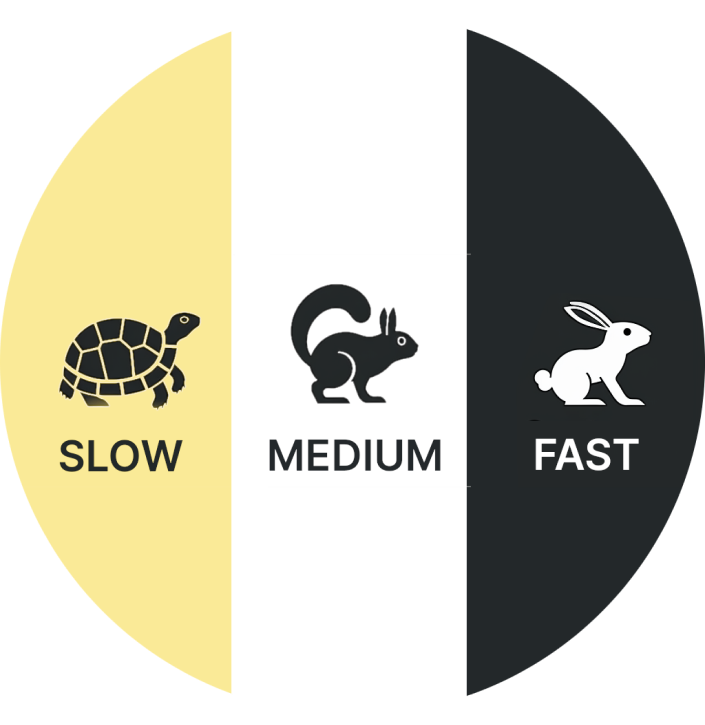

Our epoxy consists of a base and a hardener. By choosing the appropriate hardener, you determine how long it takes for the epoxy to fully cure.

- Linerwaste FAST

Curing: 3 hours to self-supporting at 20°C

Open time at 20°C: 15 minutes (time for viscosity to double) - Linerwaste MEDIUM

Curing: 6 hours to self-supporting at 20°C

Open time at 20°C: 35 minutes (time for viscosity to double) - Linerwaste SLOW

Curing: 8 hours to self-supporting at 20°C

Open time at 20°C: 50 minutes (time for viscosity to double)

All our epoxy can be ordered in a more viscous form, for example, for impregnating branch pipes.

Linerwaste - Epoxy adaptable to your situation

Our unique epoxy, available with different curing options, makes Linerwaste the simplest relining material on the market. The epoxy is designed to make the impregnation of our linings easy. After curing, our linings exhibit chemical resistance and a high E-module, matching the performance of brand-new, traditionally manufactured sewer pipes.

The installer can choose the curing time (and thus the pot life, i.e., the time you can work with the epoxy), making the epoxy suitable for both long, complex main pipelines and smaller service jobs.

Low and high viscosity

Different installers prefer different viscosities (thicknesses) of the epoxy they use. It depends on how they choose to impregnate, the type of curing used, and whether they are impregnating a main lining or a branch reinforcement, among other factors. Therefore, Linerwaste is available in low-viscosity (light-flowing) and high-viscosity (thick) variants.